Cold Storage Warehouses

Engineered Fire Protection for Extreme Cold Environments

Cold storage and refrigerated warehouses present very challenging fire protection conditions. Subzero temperatures, dry air, and high humidity differentials make traditional detection and suppression methods unreliable, yet the stakes remain high. From food preservation to pharmaceutical storage, a single incident can mean significant product loss, operational downtime, and safety risks.

KiddeFenwal delivers proven fire protection solutions designed to perform where others struggle. Our integrated detection and suppression technologies provide continuous protection for cold environments, ensuring safety and compliance without compromising temperature control or productivity.

Built for Low-Temperature, High-Risk Facilities

Cold storage warehouses are unique: the same systems that preserve goods also create complex fire challenges. KiddeFenwal solutions are engineered to meet those challenges head-on, detecting fires early, suppressing effectively, and maintaining system integrity across extreme conditions.

- Reliable Detection in Extreme Cold

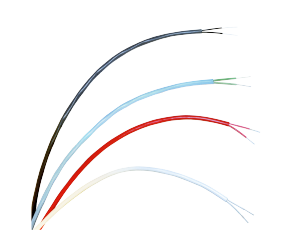

Aspirating Smoke Detection (ASD) continuously samples air and identifies fire at the earliest stages—long before visible smoke can develop, even in subzero temperatures. Linear Heat Sensors (LHS™) are also suitable for such applications to cover racks and trays especially in high-bay warehouses. - Residue-Free Suppression

Clean-agent and inert-gas systems, such as NATURA™, extinguish fires quickly without damaging products or leaving moisture or residue that could compromise inventory or insulation. - Temperature-Resilient Components

Specialized materials and system configurations prevent condensation, icing, or false alarms common in freezer environments. - Integrated System Control

Advanced detection and suppression work together for rapid response, coordinated activation, and remote system monitoring through IntelliSite™.

Applications

KiddeFenwal solutions protect a wide range of cold and temperature-controlled environments, including:

- Freezer and refrigerated warehouses

- Food and beverage storage and distribution facilities

- Pharmaceutical and biotech storage areas

- Ice cream and frozen food production plants

- Agricultural produce preservation centers

- Logistics and fulfillment hubs with cold-chain systems

Our engineers collaborate with facility designers, EHS teams, and insurers to ensure every system meets NFPA, FM Global, and local code requirements while maintaining thermal stability and product quality.

Featured Solutions

Aspirating Smoke Detection (ASD)

Ultra-sensitive early warning detection ideal for low-temperature and low-airflow conditions.

NATURA™ Inert Gas Systems

Clean, sustainable fire suppression with zero environmental impact.

Clean Agent Fire Suppression Systems

Fast, residue-free protection for cold storage and processing environments.

IntelliSite™ Remote Monitoring

Continuous performance monitoring and data-driven system insights for critical environments.

Why Choose KiddeFenwal for Cold Storage Protection

When temperature, product integrity, and uptime are critical, KiddeFenwal delivers precision fire protection engineered for cold environments.

- Purpose-Built Technology

Detection and suppression systems specifically designed for freezers, chillers, and low-temperature warehouses. - Minimal Downtime

Rapid suppression and residue-free clean agents reduce cleanup and restart time after discharge. - Early Detection Advantage

ASD and addressable detection systems identify ignition sources before damage occurs. - Environmental Responsibility

NATURA™ Inert Gas Systems provide sustainable, climate-safe suppression with zero ozone depletion potential. - Global Expertise

Trusted across food processing, logistics, and pharmaceutical industries worldwide for compliance, design, and maintenance support.

Cold Protection Without Compromise

KiddeFenwal combines early detection, intelligent control, and sustainable suppression to protect cold storage operations from the inside out. When temperature, product integrity, and uptime are on the line, trust the solutions built for the world’s coldest, most critical environments.