Dust Collectors

Fire Protection for High-Risk Dust Collection Systems

Industrial dust collection systems are essential for maintaining safe, breathable air, but they also introduce some of the most frequent and dangerous fire hazards on a production floor. Fine particulates, high air velocities, mechanical friction, and ignition sources inside ductwork and collection chambers mean that fires can ignite and spread rapidly if not detected and controlled immediately.

KiddeFenwal provides comprehensive Kidde Fire Systems branded fire detection and rapid-response suppression solutions engineered specifically for dust collection environments. Our systems help safeguard people, protect expensive equipment, and keep high-value manufacturing operations running safely and efficiently.

Fire Protection for High-Risk Dust Collection Systems

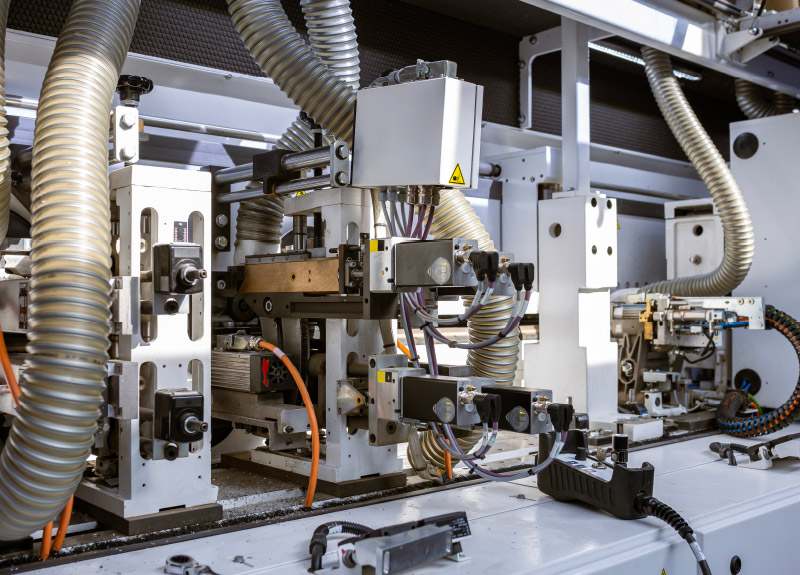

In facilities where grinding, machining, sanding, conveying, or material handling generate airborne particulates, dust collection systems are critical. These collectors, including baghouses, cartridge collectors, cyclones, scrubbers, and electrostatic precipitators, continuously pull contaminated air through filters or separation chambers.

But inside these systems, several common ignition triggers can easily develop:

- Overheating motors and bearings

- Static electrical discharge

- Burning debris pulled into the airstream

- Mechanical friction or metal-to-metal contact

- Spontaneous combustion of accumulated dust

Ignition can occur in ductwork, filters, hoppers, or even upstream equipment. Without proper fire protection, a small spark can quickly escalate into a system-wide fire event, halting production and endangering workers.

KiddeFenwal delivers targeted, code-compliant solutions that detect fire at the earliest stage, suppress flames before they spread, and minimize downtime in these high-risk environments.

Built for High-Risk, High-Velocity Airflow Environments

- Early-Stage Fire Detection

Purpose-built detection identifies sparks, heat, or combustion within ducts, filters, or hoppers before a fire spreads. - Targeted Suppression

High-pressure CO₂ systems extinguish fires rapidly in enclosed dust collector compartments and ducting. - Prevention of Rekindling

Engineered system designs provide fast discharge and deep penetration within filter media and particle beds. - Seamless System Integration

Detection, control, and suppression components work in tandem for coordinated activation and minimal equipment damage. - Application-Specific Engineering

Solutions tailored for material type, collector design, airflow volume, and environmental conditions.

Applications

KiddeFenwal solutions support a wide range of dust-generating industries and collector technologies, including:

- Industries That Rely on Dust Collection Safety

- Wood processing

- Metal fabrication

- Steel production

- Mining and minerals

- Food processing

- Agriculture and grain handling

- Chemical and petrochemical

- Paint, coatings, and finishing

- Ceramics and glass manufacturing

- Pharmaceuticals

- Types of Dust Collectors

- Baghouse collectors

- Cartridge collectors

- Cyclone separators

- Electrostatic precipitators

- Mist collectors and scrubbers

- Wet dust collectors

Our applications engineering team works with channel partners (engineered systems integrators) OEMs, and end users to determine the right detection, activation, suppression, and venting requirements for each dust collection application.

Featured Solutions

High-Pressure CO₂ Systems

Fast, residue-free suppression ideal for enclosed dust collector compartments and ductwork.

Dry Chemical Fire Suppression

Effective protection for high-temperature or fast-moving combustion risks.

Conventional Detection & Control

Reliable monitoring and system activation for dust-producing environments.

Notification Appliances

Audible and visual alerts to support safe evacuation and maintenance response.

Why Choose KiddeFenwal for Dust Collector Protection

When ignition can occur in seconds, facilities need protection engineered for harsh, dust-laden operating conditions.

- Proven Suppression Technologies

High-pressure CO₂ systems deliver rapid flame knockdown in ductwork and collector housings. - Reliable Detection

Sensors and controls are designed to perform in environments with vibration, dust loading, and fluctuating temperatures. - Process-Driven Integration

Systems interface with fans, dampers, abort gates, and shutdown sequences to minimize spread and equipment damage. - Customized Protection Strategies

Engineered solutions tailored to collector type, particulate characteristics, and facility layout. - Global Support Network

Backed by KiddeFenwal channel partners worldwide.

Together, these technologies help reduce fire risk, protect critical equipment, and support safe, continuous operation in demanding industrial environments.

Keep Your Facility Safe and Productive

Dust collectors play a critical role in workplace safety, and protecting them is essential to protecting your people, equipment, and facility. KiddeFenwal delivers proven, code-compliant solutions designed to stop ignition early, prevent system-wide events, and keep industrial operations moving.