Hydronics

Reliable Ignition & Temperature Control for Heat-Driven Systems

Heating systems must operate flawlessly, through seasonal demand, constant cycling, and widely varying environmental conditions. From commercial boilers to residential water heaters, manufacturers rely on KiddeFenwal line of Fenwal Controls ignition and temperature control devices for consistent ignition, temperature stability, and dependable safety performance. Our proven technologies help OEMs design appliances that deliver efficiency, durability, and safe operation in every application.

Built for Precision Heating and High-Efficiency Performance

- Reliable Ignition Across Fuel Types

Direct spark, intermittent pilot, and hot-surface ignition solutions— including proven hot-surface models for inputs above 400K BTU—ensure consistent, safe light-off in demanding hydronic applications. - Accurate Temperature Regulation

THERMOSWITCH® controllers and Snap-Disc Hi-Limit thermostats maintain tight thermal control and safeguard against overheating throughout heating cycles. - Advanced Modulation & System Control

The PIM® Control platform supports full modulation, electronic high-limit functionality, and enhanced supervision for modern boilers and water heaters. - Seamless Integration with Building Systems

RS485 connectivity enables communication with user interfaces, OEM controls, energy management systems, and diagnostic tools. - Proven Performance in Hydronic Environments

Built to thrive in long runtime conditions, fluctuating temperatures, and diverse system configurations across residential, commercial, and industrial hydronics.

Whether controlling ignition, regulating heat output, or providing fail-safe temperature protection, Fenwal Controls branded solutions from KiddeFenwal help manufacturers exceed performance expectations and safety standards.

Applications

KiddeFenwal technologies support a wide range of hydronic heating equipment, including:

- Commercial and residential boilers

- Hot water heaters

- Pool and spa heaters

- Hydronic HVAC appliances

- Modulating heating systems

- Process heating equipment requiring precise temperature control

KiddeFenwal engineers partner with OEMs to design, test, and refine system controls, ensuring every appliance meets the reliability and performance demands of today’s heating market.

Featured Solutions

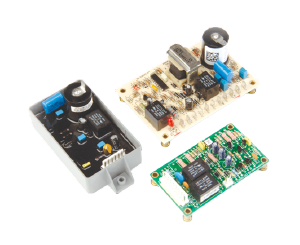

Fenwal Controls Gas Ignition Controls

Direct spark, intermittent pilot, and hot-surface ignition systems engineered for consistent performance, long service life, and operation across a range of BTU inputs.

Fenwal Controls Temperature Controls and Limits

THERMOSWITCH® controllers and Hi-Limit Snap-Disc thermostats deliver precise temperature management and essential overheat protection.

Fenwal Controls PIM® Control Platform

A modular, full-featured ignition and appliance control solution supporting modulation, digital communication, advanced supervision, and flexible system integration.

Fenwal Controls Connectivity Solutions

RS485-enabled communication that integrates with displays, OEM controllers, building management systems, and diagnostic tools for smarter system oversight.

Why Choose KiddeFenwal for Hydronics

When performance, safety, and long-term reliability matter, hydronic OEMs rely on KiddeFenwal. Our ignition, temperature, and modulation technologies are proven across residential, commercial, and industrial heating markets.

- Proven Ignition Stability

Direct spark, intermittent pilot, and hot-surface ignition controls deliver consistent, repeatable performance, even in high-BTU applications. - Trusted Temperature Protection

THERMOSWITCH® and Snap-Disc Hi-Limit controllers safeguard against overheating and ensure dependable thermal regulation. - Advanced Modulation Control

The PIM® platform provides dynamic load matching, electronic limits, and enhanced system supervision for today’s high-efficiency appliances. - Seamless Integration

RS485 communications and flexible I/O support allow easy connection to OEM electronics, user interfaces, and building or energy management systems. - Engineering Collaboration

KiddeFenwal partners closely with manufacturers to refine performance, accelerate development, and ensure every unit meets demanding hydronics standards.

From concept to deployment, KiddeFenwal helps OEMs build heating equipment that performs safely, efficiently, and reliably in every environment.

Keep Your Heating Systems Running Safely and Efficiently

KiddeFenwal delivers the ignition, control, and safety technologies that hydronic applications depend on. Whether upgrading existing designs or developing next-generation equipment, our engineering team is ready to support your goals.