Cement Plants

Reliable Fire Protection for the Backbone of Modern Infrastructure

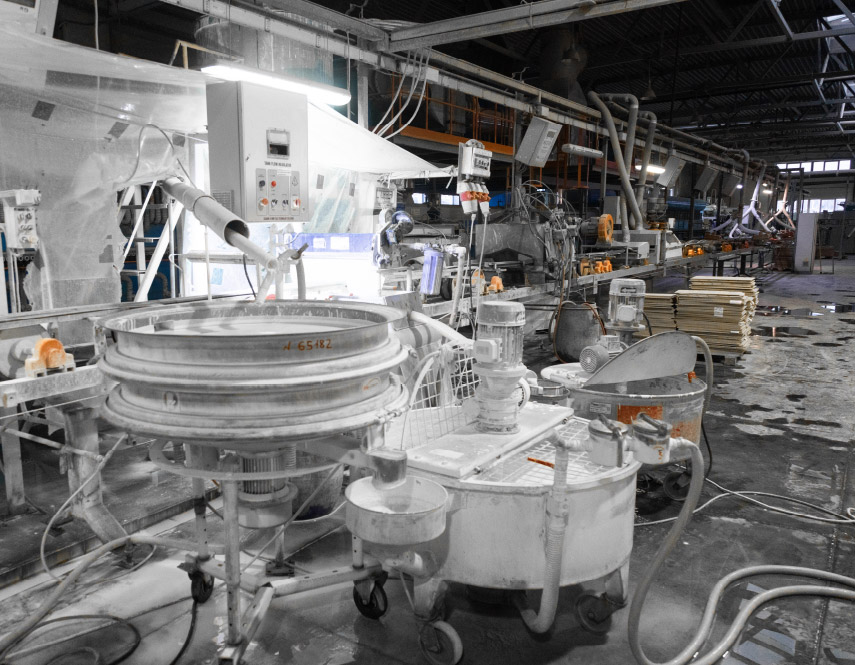

The cement and lime industry depends on continuous, high-temperature operations where even brief interruptions can have significant financial and safety impacts. With coal and coke systems now standard in many facilities, the risk of combustion and explosion from fine particulates and heated air systems is ever-present.

KiddeFenwal delivers reliable Kidde Fire Systems branded detection, suppression, and inerting solutions designed to protect critical operations, from coal grinding and fuel storage to dust collection and conveyance systems. Our CO₂ fire suppression and inerting technologies help mitigate risk, safeguard workers, and ensure production continuity across complex plant networks.

Built for High-Heat, High-Risk Environments

Cement production demands nonstop performance in extreme conditions where a single ignition can jeopardize both worker safety and operational uptime. KiddeFenwal solutions are purpose-built to perform in the demanding environments of cement and lime production. From grinding mills to dust collection networks, our systems are engineered to detect, suppress, and prevent combustion events before they threaten people, assets, or productivity.

- Targeted Suppression

CO₂ systems extinguish fires rapidly in conveyance networks and dust collection systems based on NFPA 12 standards. - Preventive Inerting

Vapor CO₂ injection minimizes spontaneous combustion in fuel bins and silos during idle or restart conditions. - Continuous Protection

Engineered detection and control solutions integrate with process systems for real-time monitoring and fast activation. - Tailored Integration

KiddeFenwal experts help configure comprehensive protection strategies for the specific application.

Applications

KiddeFenwal solutions protect critical processes and equipment throughout cement and lime production facilities, including:

- Coal Mills and Pulverizers

- Cyclones and Dust Collectors

- Surge and Fuel Bins

- Raw Coal and Coke Silos

- Interconnected Ductwork

KiddeFenwal’s engineers collaborate with plant operators and safety teams to design fully integrated fire protection strategies that address the unique hazards of each application.

Featured Solutions

Gaseous Fire Suppression Systems – High-Pressure CO₂

Reliable suppression for fuel conveyance and dust collection systems.

Detection & Control Systems – Conventional and Intelligent

Integrated monitoring and control panels ensure quick response and system reliability.

Portable Fire Extinguishers

Fast-acting, localized protection for maintenance and inspection areas.

Why Choose KiddeFenwal for Cement Plant Protection

In an industry where uptime is critical and fire risks are constant, cement manufacturers rely on KiddeFenwal for proven, integrated protection. Our solutions combine decades of field experience with advanced suppression and control technologies designed to safeguard complex material-handling systems.

- Proven Reliability:

CO₂ suppression and inerting systems engineered to perform in high-temperature, dust-laden environments typical of cement production. - Specialized Expertise:

Purpose-built solutions to mitigate spontaneous combustion and ignition in pulverized coal and coke processes. - Integrated System Design:

Seamless interoperability with existing detection, control, and process monitoring infrastructure. - Code-Compliant Assurance:

Fully engineered to meet NFPA 12 standards and plant-specific safety requirements. - Global Support Network:

Backed by certified distributors and service professionals providing technical expertise worldwide.

Dependable Safety for Continuous Operation

From fuel preparation to clinker production, KiddeFenwal delivers comprehensive fire protection engineered for the toughest industrial environments. Protect your people, assets, and uptime with solutions proven to perform under pressure.