Heat Treating Processes

Advanced Fire Protection Engineered For High-Temperature Industrial Environments

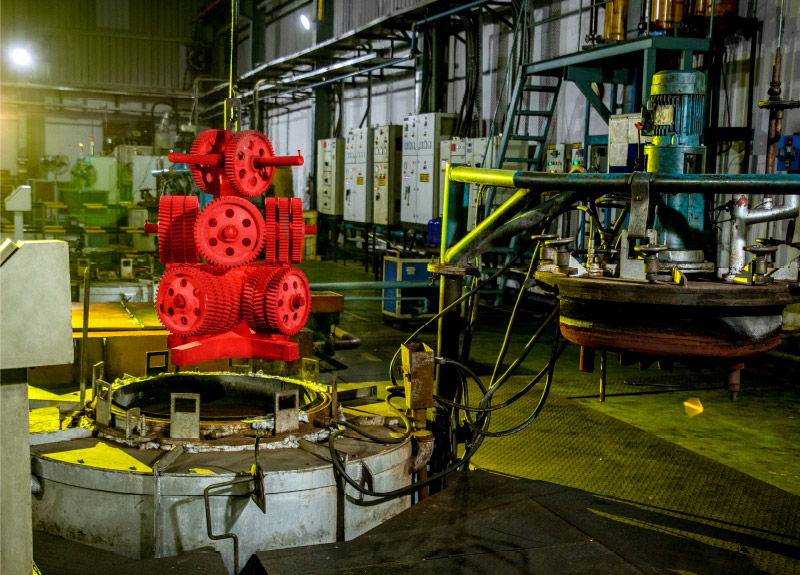

Heat treating operations play a critical role in producing durable, high-performance metal components. But with extreme temperatures, vaporized oils, and continuous cycling, these environments present some of the most challenging fire risks in manufacturing. KiddeFenwal delivers Kidde Fire Systems branded detection and suppression solutions built to protect personnel, equipment, and production continuity, even in the harshest conditions.

Understanding the Risk of Heat Treating Processes

High heat, flammable oils, and constant motion create a perfect storm for industrial fires.

Heat treating involves heating metals to precise temperatures inside industrial furnaces, then rapidly cooling them using air, salt, specialized quench fluids, or oil. Oil-quench systems, the most common method, introduce significant fire hazards:

- Vaporized oil can ignite inside open or enclosed quench tanks

- Drip pans and oil-coated components can accumulate residual fuel

- Fume hoods and exhaust ducts can pull burning vapors into confined spaces

- Continuous furnace throughput increases the risk of ignition

- Restart conditions may expose overheated oil to fresh oxygen

Without fast detection and immediate suppression, fires can escalate rapidly, endangering workers and causing costly downtime.

Built for Extreme Industrial Conditions

Fast-acting suppression and early detection reduce risk in high-hazard environments.

- Rapid CO₂ Suppression

High-pressure CO₂ systems smother surface fires on oil baths, drainboards, and exhaust areas within seconds — protecting equipment and personnel. - Process-Integrated Detection

Heat detectors monitor conveyor paths, quench tanks, and ducts for rapid ignition events. - Continuous Monitoring

Smart control systems provide real-time oversight of critical areas where temperature extremes and oil vapors are constant. - Flexible System Design

Solutions can be configured for open, partially enclosed, and fully enclosed quench tanks, including auxiliary hazard zones.

Applications

KiddeFenwal fire protection and detection technologies support a wide range of heat-treating operations, including:

- Open quench tank systems

- Enclosed quench tanks and quench cells

- Furnace discharge and conveyor areas

- Oil drip pans and drainboards

- Fume hoods and exhaust ductwork

- Heat-treat process lines and finishing areas

- Auxiliary electrical rooms and control cabinets

Our engineers work directly with manufacturers and facilities to tailor solutions that meet equipment design, quench methods, and operational requirements.

Our applications engineering team works with channel partners (engineered systems integrators) OEMs, and end users to determine the right detection, activation, suppression, and venting requirements for each dust collection application.

Featured Solutions

High-Pressure CO₂ Systems

A fast-acting, residue-free suppression solution ideal for oil-quench tanks, drainboards, ducts, and fume hoods.

Detection & Control Systems

Conventional: Reliable, responsive control panels and detection technologies that ensure rapid activation during ignition events.

Detection & Control Systems

Intelligent: Addressable detection for detailed monitoring across complex furnace and quench operations.

Notification Appliances

Clear, high-performance audible and visual alerts for personnel safety and emergency response.

Why Choose KiddeFenwal for Heat Treating Operations

Your operation demands reliability, precision, and safety, and so do your fire protection systems.

- Purpose-Built Protection

CO₂ suppression and advanced detection engineered specifically for quench tanks, exhaust systems, and high-temperature process equipment. - Early Intervention

Fast-acting sensors and panel logic identify ignition at its earliest stage, helping contain hazards before they spread. - Seamless Integration

Flexible systems engineered to complement existing furnace controls, production lines, and ventilation systems. - Compliance With Industry Codes

Solutions designed to align with NFPA and industrial fire protection requirements. - Proven Industrial Expertise

Trusted by global manufacturers who rely on heat treating to deliver their highest-value products.

Industrial-Strength Protection That Keeps Production Moving

Heat treat operations can’t afford downtime, and neither can your customers. KiddeFenwal systems provide fast, reliable detection and suppression tailored to the unique hazards of quenching, furnaces, and vapor-rich environments. Our engineered solutions help safeguard people, protect assets, and keep production on schedule.