Paint Booths & Flammable Material Storage

Fire Protection Engineered for High-Risk Spray, Coating, and Chemical Storage Environments

Paint spray booths, surface finishing lines, and flammable liquid storage areas contain some of the most hazardous combinations in industrial environments: volatile solvents, atomized coatings, ignition sources, and confined spaces where fires can ignite and spread rapidly. Whether in automotive refinishing, manufacturing, aerospace, or industrial coating operations, a single spark can cause catastrophic damage, production downtime, and significant safety risks.

KiddeFenwal delivers advanced fire detection, suppression, and monitoring systems specifically engineered to protect these volatile environments. Our solutions safeguard workers, equipment, and facilities from fires that can emerge in spray booths, mixing rooms, storage cabinets, and exhaust ductwork, ensuring continuity and compliance in operations where fire risk is always present.

Built for High-Volatility Finishing & Chemical Storage Environments

Paint booths and flammable storage applications require fire protection systems that react immediately, perform reliably under harsh conditions, and suppress fires before vapor ignition leads to flashover.

- Fast-Acting Dry Chemical Suppression

Pre-engineered dry chemical systems deliver rapid flame knockdown and are proven effective in spray booths, ducts, plenums, and areas with high concentrations of flammable vapors. - Early Detection in Difficult Spaces

Mechanical thermal detection technologies monitor hard-to-reach areas such as ducts, exhaust systems, mixing rooms, and chemical storage enclosures. - Continuous 24/7 Protection

Automatic detection and release mechanisms ensure suppression even when facilities are unoccupied, preventing after-hours ignition from solvents, overspray, or electrical faults. - Hazard-Specific System Integration

Detection, control units, supervisory devices, and suppression systems operate as a unified network to minimize spread and trigger equipment shutoff sequences. - Explosion & Flash Fire Risk Mitigation

Solutions engineered for environments with suspended particulates, aerosols, and volatile organic compounds (VOCs) that elevate ignition potential. - Regulatory Alignment

Systems designed to support compliance with NFPA 33 (Spray Applications), NFPA 30 (Flammable Liquids), OSHA requirements, and local fire code authorities (AHJs).

Applications

KiddeFenwal solutions protect a broad spectrum of spray finishing, coating, and flammable material storage environments.

- Paint & Finishing Facilities

- Automotive paint spray booths

- Industrial and production-line spray booths

- Aerospace coating facilities

- Wood finishing and furniture spray areas

- Powder coating systems

- Robotic and automated spray lines

- Exhaust & Ventilation Hazards

- Spray booth ductwork and exhaust plenums

- Overspray collection chambers

- Air filtration housings

- Fan housings and ventilation shafts

- Flammable Material Storage & Handling

- Paint mixing rooms

- Solvent and chemical storage areas

- NFPA 30 flammable liquid cabinets

- Bulk chemical drums and container storage

- Resin storage and dispensing rooms

- Aerosol storage areas

- Temperature-controlled hazardous material rooms

- Operational Support Areas

- Control rooms supporting finishing lines

- Electrical and compressor spaces serving booths

- HVAC systems that handle vapor management

KiddeFenwal application engineers work with facility owners, integrators, and AHJs to design systems that address the specific hazards of each finishing or storage environment.

Featured Solutions (KiddeFenwal)

Aspirating Smoke Detection (ASD™)

Provides early fire detection for cleanrooms, MRI control spaces, sterile manufacturing, and environments where airflow and dilution challenge traditional sensors.

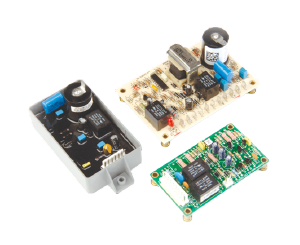

Intelligent, Conventional & Specialty Detection Systems

Networked or standalone detection and control for hospital campuses, imaging centers, labs, and pharmaceutical facilities.

Clean Agent Fire Suppression

Residue-free protection for control rooms, electronics, or areas adjacent to finishing systems where water or dry chemicals could damage equipment.

Notification Appliances

Clear, code-compliant audio/visual alerts support rapid evacuation and response.

Featured Solutions (Fenwal Controls)

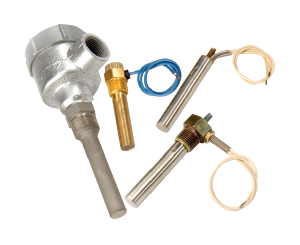

DETECT-A-FIRE® Heat Detectors

Robust thermal detection for flammable liquid storage rooms, mixing spaces, and hazardous locations requiring dependable activation under demanding conditions.

THERMOSWITCH® Temperature Controls

Mechanical temperature limiting for ovens, curing equipment, and heaters supporting finishing operations.

Gas Ignition Controls

Reliable ignition and flame-monitoring systems for industrial heating and curing equipment used alongside finishing processes.

Why Choose KiddeFenwal for Paint Booth & Flammable Storage Protection

Facilities that rely on coatings, solvents, and flammable liquids require fire protection systems they can trust, and KiddeFenwal brings decades of proven industry experience.

- Application-Specific Suppression

Pre-engineered dry chemical systems designed precisely for spray booth hazards and ductwork ignition risks. - Minimized Downtime

Rapid suppression prevents broader facility damage and keeps production lines running efficiently. - Regulatory & Insurance Compliance

Solutions that help facilities meet NFPA, OSHA, and insurance requirements for spray finishing and flammable liquid storage. - Integrated Hazard Control

Systems can be configured to shut down fans, conveyors, and electrical systems instantly to help limit fire spread. - Trusted Expertise

Backed by Kidde Fire Systems’ proven performance in industrial fire protection and Fenwal Controls’ reliability in temperature and ignition safety.

Protecting Workers, Facilities, and Operations Where Flammable Hazards Are Present

From automotive refinishing to industrial coating lines to chemical storage environments, KiddeFenwal provides advanced detection and suppression technologies that help prevent catastrophic fire events and safeguard your most critical operations.