Power Generation & Transmission

Fire Protection Engineered for High-Energy, High-Reliability Electrical Infrastructure

Power generation and transmission facilities are among the most critical assets in modern society. From large-scale steam electric plants to compact gas turbine units and expansive transmission networks, these environments contain intense heat sources, rotating machinery, high-voltage equipment, and flammable fuels, all operating around the clock. A single ignition can threaten worker safety, damage multi-million-dollar equipment, disrupt service to entire regions, and trigger cascading operational and financial repercussions.

KiddeFenwal delivers advanced fire detection, suppression, and system controls engineered specifically for the high-energy demands of electrical generation and transmission environments. Our solutions help safeguard turbines, cable rooms, control centers, transformers, and auxiliary systems, ensuring operational continuity where uptime is non-negotiable.

Built for the Extreme Demands of Power Generation & Transmission

Power facilities require fire protection systems that perform reliably in high-temperature, high-vibration, dust-laden, and electrically complex environments. KiddeFenwal solutions integrate rapid detection, engineered suppression, and intelligent monitoring to protect equipment and maintain uninterrupted electrical service.

- Rapid, Targeted Suppression

High-pressure CO₂ and clean-agent systems provide fast flame knockdown for turbines, generators, switchgear, and enclosed mechanical spaces where fire can escalate quickly. - Superior Early Detection

Air sampling smoke detection (ASD), intelligent sensors, and linear heat detection identify overheating, electrical faults, arcing, or smoldering insulation before a fire becomes visible. - Resilient to Harsh Conditions

Components engineered to withstand vibration, heat, dust, oil mist, and environmental fluctuations typical of power plants and transmission infrastructure. - Coordinated System Control

Detection, alarms, suppression release, and shutdown logic function as a unified, fully supervised network—enhancing response effectiveness and system reliability. - Broad Hazard Coverage

Solutions engineered for diverse facility types including fossil fuel plants, , renewable generation sites, substations, and transmission support facilities. - Regulatory & Insurance Compliance

Systems comply with NFPA system design and industry-specific codes and standards.

Applications

KiddeFenwal solutions protect critical hazard zones across power generation and transmission networks.

- Generation Facilities

- Steam electric plants (fossil, biomass, refuse-derived)

- Gas turbine generator enclosures

- Combined-cycle power plants

- Hydroelectric auxiliary rooms

- Renewable energy support buildings

- High-Risk Equipment Areas

- Turbines and turbine compartments

- Generators and excitation equipment

- Lube oil skids and hydraulic systems

- Fuel oil tanks and pump rooms

- Compressor housings

- Boiler and combustion support equipment

- Electrical Distribution Infrastructure

- Switchgear rooms

- Cable trays and cable vaults

- Transformer rooms

- Electrical control centers

- Relay rooms and substations

- Operational & Support Spaces

- Control rooms and monitoring centers

- Equipment storage sheds

- Maintenance workshops

- MCC rooms (motor control centers)

- Auxiliary mechanical spaces

KiddeFenwal engineers collaborate with utilities, EPC firms, and system integrators to design application-specific solutions that support uptime, safety, and compliance across the full energy ecosystem.

Featured Solutions (KiddeFenwal)

High-Pressure CO₂ Fire Suppression

Ideal for turbines, generators, enclosed mechanical spaces, and high-hazard areas requiring rapid suppression and maximum uptime.

Clean Agent Fire Suppression (HFC-227ea, Fluoro-K™, NATURA™)

Residue-free protection for control rooms, switchgear, electrical distribution centers, and sensitive electronics.

Air Sampling Smoke Detection (ASD)

Early detection for cable trays, electrical rooms, turbine enclosures, and areas with strong airflow or particulate presence.

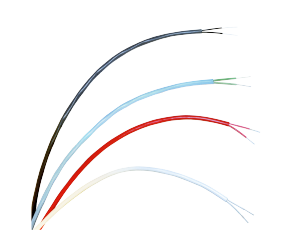

Linear Heat Detection

Durable, continuous heat-sensing cable ideal for cable trays, vaults, tunnels, ducts, and hard-to-access areas.

Conventional & Intelligent Detection and Control Systems

Multi-loop intelligent panels, networkable controls, and supervisory logic designed for large-scale electrical facilities.

Notification Appliances

High-output audible and visual devices engineered for noisy industrial environments.

Featured Solutions (Fenwal Controls)

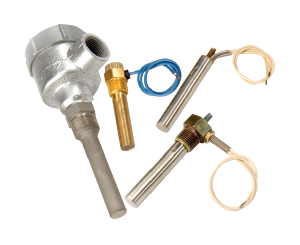

DETECT-A-FIRE® Heat Detectors

Reliable fixed-temperature detection for transformer rooms, mechanical enclosures, and auxiliary heat-producing equipment.

THERMOSWITCH® Temperature Controllers

Mechanical temperature limiting for lubrication systems, combustion support equipment, and industrial heating applications.

Why Choose KiddeFenwal for Power Generation & Transmission Protection

Power facilities demand uncompromising reliability, and KiddeFenwal is trusted across the global energy sector to deliver performance when it matters most.

- Proven Industrial Expertise

Decades of experience protecting turbines, generators, and electrical infrastructure in complex energy environments. - Early Warning Detection

ASD, intelligent sensing, and linear heat systems identify electrical faults and overheating long before failures occur. - Fast, Effective Suppression

CO₂ and clean agents systems minimize damage and support critical uptime. - System Integration Across Large Facilities

Multi-loop, networkable controls deliver coordinated monitoring and release operations. - Harsh-Environment Durabilit

Engineered for vibration, dust, heat, oil vapor, and continuous-duty operation. - Commitment to Operational Continuity

Systems designed to preserve capital assets and maintain uninterrupted electrical service.

Protecting the Infrastructure That Powers the World

From massive steam electric stations to compact turbine installations and transmission support facilities, KiddeFenwal delivers engineered fire protection that keeps essential energy systems safe, reliable, and operational.