Printing Presses & Plants

Fire Protection for High-Speed Presses, Coating Lines, and Flammable Ink Environments

Modern printing plants operate at extremely high speeds and involve materials that can ignite easily under the right conditions. Solvent-based inks, flammable coatings, lubricants, hydraulic fluids, rolls of paper, and fine dust particulates all come together around motors, drying systems, friction points, and high-energy mechanical motion. In seconds, a small ignition can escalate into a fire that threatens operators, damages large web or gravure presses, and halts production schedules.

KiddeFenwal delivers advanced detection, suppression, and system controls engineered specifically for the printing industry. Our solutions provide rapid, targeted fire protection for printing presses, coating lines, curing ovens, ink storage rooms, and auxiliary machinery, ensuring safer operations, reduced downtime, and dependable protection of high-value equipment.

Built for High-Velocity, High-Flammability Printing Environments

Printing facilities require fire protection systems that operate instantly, perform reliably in dusty or solvent-rich atmospheres, and integrate tightly with press machinery for coordinated response.

- Fast Suppression for Press and Dryer Hazards

High-pressure CO₂ provide rapid extinguishment of flames in enclosed press components, dryers, rewinders, and coating equipment. - Early Detection Across Complex Machinery

Intelligent detection, conventional sensors, and linear heat detection monitor bearings, rollers, motors, ducts, and curing systems where fires may begin undetected. - Solvent & Ink Hazard Mitigation

Clean-agent and CO₂ systems minimize damage to sensitive machinery and electronics involved in printing, coating, and laminating processes. - Press Integration & Automatic Shutdown

Systems interface with machine controls to shut down presses, stop web movement, halt dryers, and close dampers—limiting fire spread and protecting operators. - Protection Against Dust & Static Ignition

Detection and suppression solutions designed for areas where airborne paper dust, lint, and static electricity can increase combustion risk. - Compliance with Industry Standards

Solutions support NFPA, OSHA, and insurance requirements for printing operations, ink handling, and flammable liquid storage.

Applications

KiddeFenwal solutions safeguard every stage of printing, coating, and finishing operations, including:

- Press & Printing Line Protection

- Web printing presses

- Flexographic presses

- Rotogravure printing

- Gravure and flexo coating lines

- Newspaper and publication presses

- Sheet-fed printing systems

- High-Heat Processes

- Curing ovens

- Dryers and IR heating systems

- Thermal and UV curing lines

- Cylinder washers and cleaning systems

- Flammable Material Handling

- Ink storage rooms

- Solvent handling and mixing areas

- Chemical and coating storage

- Hazardous materials cabinets

- Auxiliary & Support Areas

- Fluid coating machines

- Industrial spray booths

- Electrical and mechanical rooms connected to press lines

- Ventilation and exhaust plenums

- Paper staging, rewinding, and finishing areas

KiddeFenwal engineers collaborate with OEMs, plant managers, and integrators to tailor solutions that meet safety, production, and equipment-specific requirements in printing facilities of all sizes.

Featured Solutions (KiddeFenwal)

High-Pressure CO₂ Fire Suppression

Industry-preferred suppression for printing presses, enclosed machinery, dryers, and coating systems requiring fast, residue-free extinguishment.

Dry Chemical Fire Suppression Systems

Effective fire suppression for flammable ink and solvent storage rooms.

Clean-Agent Suppression (NATURA™, HFC-227ea, Fluoro-K™)

Ideal for protecting electrical rooms, press controls, plate-making systems, and sensitive equipment without residue or damage.

Air Sampling Smoke Detection (ASD)

Early warning detection for press enclosures, cable runs, electrical compartments, and areas where particulate may dilute visible smoke.

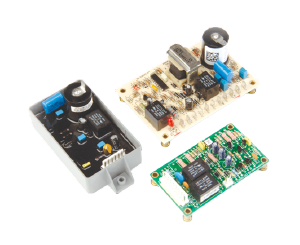

Intelligent & Conventional Control Systems

Coordinated press shutdown, alarm activation, and suppression release for complex machinery and multi-zone operations.

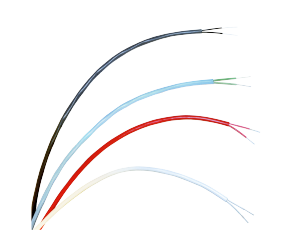

Linear Heat Detection

Continuous thermal monitoring for dryers, ductwork, ovens, cable trays, and hard-to-access equipment zones.

Notification Appliances

High-visibility, high-audibility alerts suitable for noisy production floors.

Featured Solutions (Fenwal Controls)

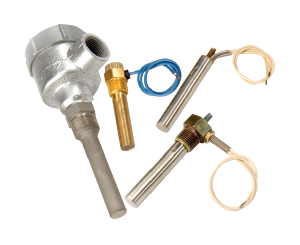

DETECT-A-FIRE® Heat Detectors

Rugged thermal detection for curing ovens, coating lines, and auxiliary machinery exposed to fluctuating temperatures.

THERMOSWITCH® Temperature Controllers

Mechanical overheat protection for curing systems, heating elements, and press-support equipment.

Gas Ignition Controls

Reliable ignition management for industrial heating components integrated into printing and finishing workflows.

Why Choose KiddeFenwal for Printing Plant Protection

Printing operations depend on precision equipment and continuous uptime—both of which require fire protection systems that act instantly, integrate seamlessly, and protect without damaging machinery.

- Purpose-Built for Press Environments

Solutions engineered for web, gravure, flexographic, and coating operations. - Rapid Suppression for High-Risk Areas

CO₂ and dry chemical systems provide fast control before a small ignition becomes a major event. - Ultra-Early Hazard Detection

Helps prevent fires in ducts, dryers, and press components where ignition may begin invisibly. - Minimal Equipment Downtime

Clean agents and CO₂ reduce collateral damage to expensive presses and support systems. - Compliance with Industry Requirements

Designed to meet the safety standards expected in flammable ink and coating environments. - Expert Application Engineering

Trusted guidance for complex printing lines, multi-stage coating systems, and custom machinery configurations.

Keeping Printing Operations Safe, Productive, and Protected

From newspaper presses to high-speed packaging lines, KiddeFenwal provides engineered fire detection and suppression solutions that safeguard workers, protect valuable equipment, and keep production running without interruption.